Removable Passive Fire Protection Rotork IQ35

FirePro Removable Passive Fire Protection Rotork IQ35, UL1709

FirePro® Passive Fire Protection Systems

FirePro® Passive Fire Protection Systems have been independently assessed and verified by both Underwriters Laboratories and Southwest Research Institute. FirePro Fire Protection Systems fulfills the requirements for UL1709 and ASTM E119 and a wide range of onshore and offshore passive fire protection guidelines and requirements.

|

ITEM |

FirePro® Fire Protection Systems ... |

FASTENING SYSTEM |

Stainless Steel Straps and Buckles |

|

THICKNESS |

2in / 51mm |

RATING |

UL1709, ASTM |

|

INSULATION MATERIAL |

High-Temperature Resistant Ceramic Fiber Core |

COLOR |

Green |

|

CORROSION |

Neutral |

WEIGHT |

55lbs/24.95kg |

|

JACKET MATERIAL |

Two Layer Design: Teflon Coated Exterior ... |

FIT |

Rotork IQ 35 |

Fire Protection Applications

- Valves

- Actuators

- Controls

- Cable Trays

- Cabinets

- Enclosures

- Pipes

- Pipe Components

Features

- Two Layer Design: Teflon Coated Exterior, High-Temperature Resistant Ceramic Fiber Core

- Corrosion Neutral

- Adjustable Strap & Buckle

- Flexible, Lightweight, Modular Pieces

- Meets & Exceeds UL1709 Rapid Rise Fire Test Duration

- Expedited Delivery Service Available

- Stainless Steel Nameplate for Easy Identification

Benefits

- Removable & Reusable

- Simple & Quick Installation

- Long Lasting & Durable

- No Tools Required

- Weatherproof, Chemical Resistant, UV Resistant

- No Equipment Downtime

- Blocks the Flame Path & Retards Heat Flow

UL1709 Certified Fire Protection

FirePro® by UniTherm is a fire protection system designed to insulate equipment and significantly delay internal temperature rise in the event of a fire. Easy to install, remove and reuse, the FirePro® product line offers a simple and effective means to protect critical process control equipment. FirePro® products meet UL1709 requirements and follow the recommended standards of API 2218.

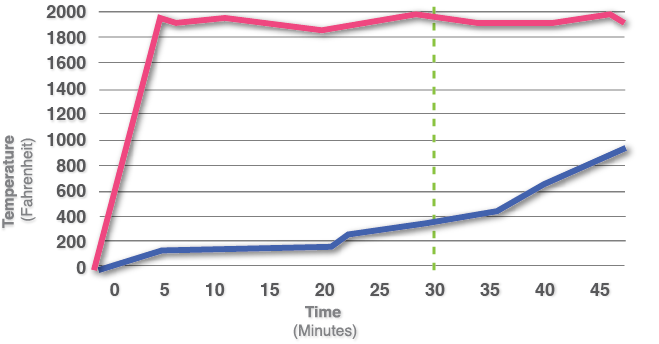

The chart above shows the results of a FirePro® system subjected to a full Hydrocarbon Fire Test that meets UL 1709 requirements.

Removable Reusable Passive Fire Protection

Molded-on coatings cannot be field applied or removed and can create serious corrosion problems leading to stress corrosion cracking and possibly premature equipment failures. These problems can undermine the integrity of the fireproofing and cause damage to your equipment. Box and enclosure fireproofing is cumbersome to remove, some require the equipment to be out of operation and uninstalled. This type of fireproofing generally exposes bare insulation creating a highly corrosive environment and requires fire seals to be replaced/reinstalled any time the box is opened to service or operate equipment. FirePro® is supported right on the equipment and does not require any mounting hardware or supports. Its flexible character makes it conform and easily adapt to the exact shape of the equipment assembly. This form fitting cover will generally not obscure or distort the appearance of equipment to the point that it is unidentifiable.

FAQ's

Q: What level of passive fire protection does FirePro® provide?

A: FirePro® is a versatile and flexible system for protecting critical control equipment in a UL1709 fire that reaches temperatures of 2000°F (1103°C) for at least 30 minutes.

Q: What information do you need to have in order to build a FirePro® cover that fits properly?

A: Typically, you will only need a model number of the actuator and a short, detailed, technical description of any accessories that are mounted on the actuator. OR You can submit a 3D DWG file that shows the assembly of your actuator.

Q: How are controls... buttons, dials, gages...etc. accessed with a FirePro® cover installed?

A: FirePro® blankets are pre-engineered with openings and access doors, making it easy to access critical control elements for operation or maintenance. Handwheels, declutch levers, push buttons, knobs and other key controls can usually be extended outside of fireproofing to ensure direct access, which adheres to the standards outlined in API 2218.